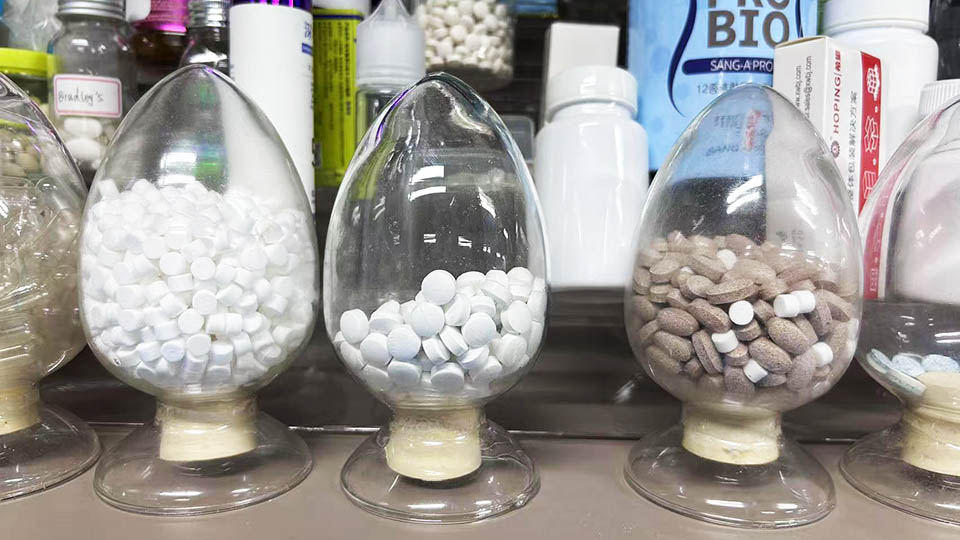

Таблетка — компактная, сферическая или овальная лекарственная форма, относящаяся к наиболее распространённым лекарственным средствам. К ним относятся как рецептурные, так и безрецептурные препараты. мед икация s. Таблетки, разработанные в различных размерах, формах и составах, включая таблетки и капсулы обеспечить точную и эффективную доставку определенных доз лекарств в организм ии . Этот термин охватывает таблетки, капсулы и аналогичные твердые пероральные препараты, обычно принимаемые внутрь, но иногда и сублингвально. Их популярность приходить s от convenien t использования , портативность и точное дозирование.

Обширный , другой типы Выбор таблеток зависит от потребностей пациента и терапевтических целей. Различные формы выпуска учитывают такие факторы, как скорость абсорбции, лёгкость проглатывания и стабильность препарата в желудочной среде. Некоторые типы таблетка таблетка-капсула имеют механизмы контролируемого высвобождения для постепенного активного Доставка ингредиентов, в то время как другие обеспечивают немедленное облегчение. Эти варианты обеспечивают наиболее подходящий способ введения лекарств, адаптируя лечение к индивидуальным потребностям пациента.

|

Тип с таблеток |

Характеристики |

Функция |

Преимущества |

|

Твердые капсулы |

Порошкообразный препарат, заключенный в желатиновую оболочку, обеспечивает точную дозировку для стабильных составов, таких как витамины и лекарственные ингредиенты. |

Обеспечивает дозирование и поддержание стабильности витаминов и лекарства |

Точная дозировка, идеальная для лекарственных форм |

|

Мягкие капсулы |

Жидкое или полужидкое лекарство, заключенное в мягкую желатиновую оболочку, обеспечивающую быстрое растворение в желудке. |

Способствует быстрому усвоению; часто используется в добавках, таких как масла омега-3. |

Быстрое усвоение, эффективно для добавок быстрого действия |

|

Капсулы для посыпки |

Лекарство в форме небольших гранул, которое можно смешивать с едой или напитками, подходит для пациентов с проблемами глотания. |

Обеспечивает альтернативный метод введения для лиц (например, детей, пожилых людей), которые может иметь трудности в глотание |

Удобен для пациентов с дисфагией, адаптируемый к потребностям |

|

Обычные таблетки |

Твердые лекарственные формы с покрытием, содержащие большие объемы лекарственного средства, предназначенные для лечения хронических заболеваний с замедленным высвобождением |

Обеспечивает контролируемое, постепенное высвобождение препарата для долгосрочного лечения заболевания |

Надежный профиль высвобождения, оптимизированный для хронической терапии |

|

Жевательные таблетки |

Разработано для разжевывания перед проглатыванием, что упрощает прием для детей и людей с трудностями глотания. |

обычно используется для витаминов и лекарство с |

Облегчает применение препарата пациентами с дисфагией, особенно в педиатрии и гериатрии. Не требует глотания, часто ароматизирован для улучшения вкусовых качеств. |

|

Таблетки для рассасывания |

Быстро растворяется во рту без воды, подходит для быстрого облегчения симптомов или для пациентов, неспособных глотать таблетки. |

Обеспечивает мгновенную доставку лекарств, что критически важно при острых симптомах |

Безводное введение, быстродействующее средство для экстренных случаев |

|

Шипучие таблетки |

Разработан для растворения в воде с получением газированного напитка. |

улучшает всасывание и облегчает прием лекарств пациентами, не приемлящими таблетки |

Ускоряет всасывание лекарств; рекомендуется тем, кто не любит твёрдые таблетки. Упрощённый приём, более быстрое системное усвоение. |

· Твердые капсулы

Эти капсулы, изготовленные на машине для наполнения капсул, состоят из желатиновой оболочки, содержащей порошкообразное лекарство, предназначенное для точного дозирования и стабильных формул, таких как витамины и лекарство с.

· Мягкие капсулы

С гибкой желатиновой оболочкой с Мягкие капсулы инкапсулируют жидкие или полужидкие лекарственные вещества и быстро растворяются в желудке. Они идеально подходят для быстроусвояемых добавок, таких как рыбий жир.

Эти капсулы, обычно инкапсулированные с помощью машины для наполнения капсул, содержат небольшие гранулы, которые можно посыпать пищей или смешивать с жидкостями, что делает их удобным вариантом для детей и пожилых пациентов с трудностями глотания.

Капсулы выпускаются в различных формах для удовлетворения различных потребностей пациентов. Твёрдые капсулы обеспечивают точность дозировки стабильных соединений, а мягкие капсулы оптимизируют быстрое всасывание. Капсулы с посыпкой облегчают приём препарата тем, кому сложно его проглотить, позволяя смешивать его с пищей или водой. Каждый тип разработан для максимальной терапевтической эффективности в зависимости от назначения препарата и потребностей пациента.

1.2 Планшет с и их использование

Эти высокодозированные препараты, покрытые оболочкой для контролируемого высвобождения лекарство таблетки , изготовленный с помощью таблеточной машины, предназначены для хронические состояния, требующие постоянного и длительного приема лекарств.

Эти таблетки предназначены для разжевывания, а не для глотания целиком. таблетки лекарств удобны для пациентов с дисфагией и широко используются для витамины или лекарство с.

Эти таблетки мгновенно растворяются во рту без воды, что является удобным решением для пациентов с острыми состояниями и проблемами глотания.

При растворении в воде они образуют газированный напиток, который быстро усваивается. идеально подходит для людей, которые предпочитают жидкую форму приема твердым таблеткам.

Таблетки , обычно изготавливаемый с помощью таблеточной машины, разработаны различными способами, чтобы соответствовать предпочтениям пациента и медицинским потребностям. медикамент Таблетки обеспечивают постоянное высвобождение лекарственного средства для длительной терапии, при этом жевательные и таблетка, распадающаяся во рту Мы уделяем первостепенное внимание удобству использования для людей с проблемами глотания. Шипучие таблетки представляют собой приятную на вкус альтернативу с быстрым всасыванием. Все варианты направлены на повышение эффективности лечения и приверженности пациентов.

|

Типы таблеток |

Ключевые свойства |

Продолжительность и действие |

|

Таблетки с немедленным высвобождением |

Быстро растворяются при приеме внутрь, обеспечивая поступление активного вещества для мгновенного терапевтического эффекта. |

Быстродействующий, но кратковременный, идеально подходит для облегчения острых симптомов |

|

Таблетки с пролонгированным высвобождением |

Разработан для постепенного высвобождения лекарственного средства, что позволяет минимизировать интервалы между приемами и сохранить эффективность. |

Длительное воздействие за счет постепенного высвобождения препарата |

|

Спансулы (капсулы с замедленным высвобождением) |

Содержат гранулы в желатиновой оболочке, что обеспечивает контролируемое растворение препарата во времени |

Обеспечивает равномерное всасывание, гарантируя стабильную концентрацию в крови |

Таблетки с немедленным высвобождением разработаны для быстрого распада при приеме внутрь, обеспечивая мгновенную доставку активных компонентов в организм. Эти препараты таблетки обычно используются при острых состояниях, требующих быстрого облегчение симптомов, таких как головная боль или внезапная боль.

Расширенный выпуск таблетки Разработаны для постепенного высвобождения препарата в течение длительного времени, что снижает необходимость в частом приеме. Это делает их подходящими для лечения хронических заболеваний, таких как диабет, где важно поддерживать постоянную концентрацию препарата. Такие составы часто содержат специальные покрытия или слоистые структуры для контроля скорости высвобождения, обеспечивая стабильную концентрацию препарата в кровотоке.

Спансулы – это твердые желатиновые капсулы, предназначенные для контролируемого, зависящего от времени высвобождения лекарственного вещества. Они состоят из множества небольших гранула s или гранулы с разной толщиной покрытия, растворяющиеся с разной скоростью. Этот механизм постепенного высвобождения обеспечивает этот тип таблетки особенно эффективен при расстройствах, требующих постоянного приема лекарств.

|

Типы таблеток |

Ключевые особенности |

Предполагаемое использование |

|

Жевательные таблетки |

Понимание блистерных упаковок CPHI Шанхай N1D50, обратный отсчёт 33 дня |