Автоматические машины для наполнения капсул стали незаменимыми в крупномасштабном производстве капсул для нутрицевтических и фармацевтических препаратов. Эти машины, отличающиеся эффективностью и точностью, могут автоматически наполнять пустые твердые желатиновые капсулы порошками, гранулами и пеллетами, что идеально подходит для производства капсул для лекарственных препаратов на фармацевтических предприятиях. Оборудование китайского производства славится своей высокой экономичностью, постоянным совершенствованием, точностью и стабильностью, соответствующими стандартам cGMP.

Машины для фасовки порошковых капсул, как правило, делятся на 3 основные категории:

Ручные капсульные наполнители — это портативные устройства, предназначенные для разделения, наполнения и повторного соединения пустых капсул из растительного сырья или желатина с порошкообразным веществом. Они используются в основном для мелкосерийного индивидуального производства с ограниченной эффективностью наполнения капсул.

А полуавтоматическая машина для наполнения капсул Это гибридная модель, которая, несмотря на наличие автоматического наполнения капсул, всё же предполагает ручное управление. Оператору необходимо выполнять такие действия, как отделение оболочек гелевых капсул, прессование порошка и закрытие наполненных капсул, в то время как такие этапы, как выдача и наполнение капсул, выполняются автоматически.

Ан автоматическая капсульная машина Система способна выполнять весь процесс наполнения капсул, включая загрузку пустых желатиновых капсул и ингредиентов, дозирование капсул, разделение капсул, наполнение капсул порошком, удаление отходов, закрытие капсул и вывод закрытых капсул, в автоматическом режиме с минимальным ручным вмешательством. Другими словами, несколькими касаниями экрана можно создать огромное количество наполненных капсул.

автоматическая машина для наполнения капсул

На практике автоматические машины для наполнения капсул незаменимы в массовом фармацевтическом производстве, и здесь мы сосредоточимся на характеристиках автоматических машин для наполнения капсул.

Перед приобретением автоматической машины для наполнения твердых капсул необходимо учесть несколько моментов:

2.1 Применение размера капсулы Автоматическая машина для капсулирования должна уметь работать с капсулами различных размеров от 000 до 5, что подходит для производителей капсул, желающих переходить к следующей партии продукции.

2.2 Производственная мощность Производительность разных моделей сильно различается. Например, производительность капсулоукладочной машины NJP 1200 в 3 раза выше, чем у NJP 400C. Вам необходимо выбрать капсулоукладочную машину в зависимости от вашего объема производства. Наиболее распространенные автоматические модели имеют производительность по наполнению капсул от 18 000 до 85 000 штук в час.

2.3 Точность Поскольку точность дозирования порошка тесно связана с однородностью веса капсул, терапевтическим эффектом лекарственного препарата и безопасностью пациента, точность систем измерения и наполнения имеет решающее значение. В международной фармацевтической промышленности точность объема наполнения капсул регулируется законодательными стандартами; например, относительное стандартное отклонение (RSD) объема наполнения должно быть менее 6%.

2.4 Материалы для машин Современная фармацевтическая капсульная машина должна быть изготовлена из нержавеющей стали, чтобы обеспечить стабильность оборудования и устойчивость к коррозии, высоким температурам и ударам. В частности, детали, контактирующие с сырьем фармацевтической продукции, должны быть изготовлены из нержавеющей стали марки 316.

2.5 Простота обслуживания Предположим, вам необходимо производить капсулы разных типов. В этом случае неизбежны переналадка оснастки и очистка компонентов. Капсульный станок должен иметь модульную конструкцию для быстрой смены пресс-форм и простоты технического обслуживания.

Выбор подходящей автоматической машины для капсулирования в первую очередь определяется несколькими ключевыми характеристиками, влияющими как на эффективность работы, так и на качество капсул. Критически важными факторами являются точность наполнения и материал конструкции машины. Кроме того, высококачественные автоматические машины для капсулирования желатина обладают рядом общих преимуществ, обеспечивающих высокую производительность. Давайте подробно рассмотрим эти преимущества.

По сравнению с обычными капсулонаполнителями, лучшие капсулонаполнители демонстрируют гораздо лучшие показатели благодаря своим высококачественным механизмам и компонентам. Например, обычный автоматический капсулонаполнитель впечатляет пользователей высокой скоростью, но пользователи формируют долгосрочное доверие к надежным полностью автоматическим капсулонаполнителям, выпускаемым известными производителями, такими как Syntegon, Romaco и другими. Богатая упаковка в соответствии с их непрерывной, стабильной работой с высокой эффективностью.

Что отличает высококачественную машину для наполнения желатиновых капсул? Имея более чем 20-летний опыт разработки моделей машин для наполнения капсул серии njp, мы рассмотрим их превосходные преимущества.

Точное наполнение является краеугольным камнем фармацевтического капсульного производства, напрямую определяя однородность веса капсул, соответствие партии требованиям и безопасность дозировки лекарственного препарата. Высококачественные автоматические капсульные наполнители обеспечивают точность веса наполнения благодаря передовым инженерным решениям и высокоточному оборудованию, такому как:

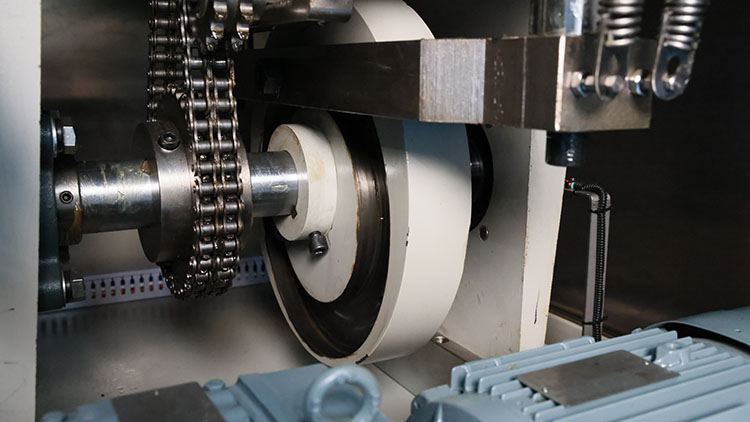

● Высокоточная система индексации: Благодаря использованию оптической делительной головки Zeiss немецкого производства, система обеспечивает безупречное угловое вращение каждой обрабатывающей станции, исключая отклонения концентричности капсульной формы и стержня наполнения в дозирующем диске. Цельнофрезерованный индексирующий вал дополнительно гарантирует выравнивание, что способствует низкой погрешности веса наполнения ≤3%.

●Встроенные кулачки: В этих автоматических машинах для изготовления капсул используются встроенные внутренние кулачки с двумя гранями. Такая конструкция соединяет два колеблющихся рычага с внутренними пазами кулачков, равномерно распределяя усилие во время работы. Это устраняет вибрацию и нестабильность, характерные для внешних кулачков с одной гранью, обеспечивая надежную основу для всего механизма наполнения.

Таким образом, синергия безупречной системы индексации и виброгасящего кулачкового механизма преобразует механическое воздействие в надежную точность, позволяя каждой капсуле соответствовать строго заданным параметрам веса наполнения.

Хотя высокая производительность в час является общепринятым критерием для автоматизированных коммерческих машин для наполнения капсул, истинное промышленное совершенство измеряется способностью к длительной стабильной работе. Поддержание скорости наполнения десятков тысяч капсул в час в течение продолжительных смен (более 12 часов) является важнейшим испытанием, отличающим стандартные капсульные машины от лучших производителей капсул.

Стабильность инкапсуляции является результатом целостного инженерного подхода, ориентированного на долговечность и контроль загрязнения, который включает в себя:

●Высокоточный кулачковый индексатор: Прецизионные кулачковые индексаторы 100DS, используемые производителями машин для наполнения капсул, такими как Rich Packing, обеспечивают непревзойденный контроль движения и структурную целостность, исключая частые отказы и простои, связанные с некачественными индексаторами 83DS.

●Технология герметизации башни: Главная башня оснащена силиконовыми уплотнительными кольцами, которые предотвращают попадание пороха внутрь, избегая заклинивания во время работы из-за закупорки порохом.

●Усовершенствованная обработка поверхности: микроэлектронная полировка стержней наполнителя, отверстий капсульных форм и дозирующих дисков обеспечивает оптимальную текучесть порошка. Эта критически важная обработка предотвращает прилипание и накопление мелких, липких или гигроскопичных порошков, тем самым предотвращая остановку оборудования из-за их скопления.

Помимо вышеперечисленных особенностей, высококлассная машина для наполнения крышек включает в себя интеллектуальные системы терморегулирования, виброгасящие конструкции и датчики мониторинга в реальном времени. Эти элементы работают согласованно, гарантируя стабильность и предсказуемость результатов в крупномасштабном фармацевтическом производстве.

Среди всех проблем в производстве фармацевтических капсул контроль утечки порошка во время высокоскоростного наполнения капсул является критически важной, поскольку он влияет на стабильность процесса наполнения. Представьте, что ваша машина для производства желатиновых капсул заполнена остатками порошка. Как можно обеспечить гигиеничность фармацевтического производства и предотвратить накопление порошка, которое приводит к застреванию компонентов?

Высококачественные автоматические машины для наполнения капсул решают эту проблему с помощью трехкомпонентной стратегии, включающей высокоточное проектирование, подготовку порошка и инновационные методы герметизации.

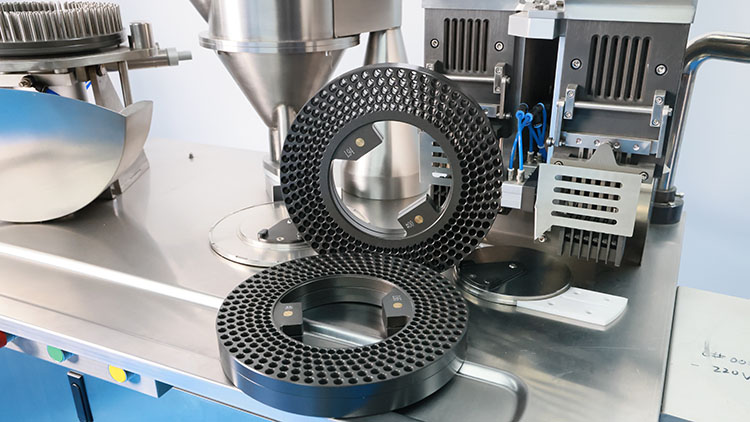

● Высокоточная оснастка: Формы, включая верхние и нижние отверстия для капсул, дозирующие диски и трамбовочные штифты, обрабатываются с точностью до микрометра, обеспечивая практически идеальное уплотнение с корпусами капсул. Такая высокоточная обработка минимизирует микроскопические зазоры, через которые мелкий порошок мог бы просачиваться под действием центробежной силы.

●Интеллектуальная подготовка порошка: Автоматическая установка для капсулирования njp использует станцию уплотнения, которая бережно предварительно уплотняет порошок внутри капсул после их заполнения. Эта стадия уплотнения повышает когезионную плотность порошка, снижая вероятность его разлета в воздухе из-за вибрации инструмента или быстрого вращения револьверной головки.

●Активная герметизация: В современных машинах для наполнения капсул используются локальные вакуумные отводные отверстия в местах потенциальной утечки порошка, например, вокруг дозирующего диска или станции запирания капсул. Эти отверстия удаляют любой посторонний порошок. Кроме того, такая механическая конструкция часто включает в себя крышки, воздушные завесы или зоны избыточного давления для удержания и перенаправления воздушного потока, предотвращая разжижение и диспергирование порошка внутри капсульных форм.

Благодаря синергии этих механизмов — от прецизионного инструмента для минимизации зазоров и контролируемого уплотнения для стабилизации порошка до активных устройств для управления потоком воздуха — превосходные машины для наполнения капсул обеспечивают идеальное удержание порошка, минимизируя перекрестное загрязнение и поддерживая чистоту производственной среды.

Предотвращение столкновений внутренних компонентов имеет решающее значение для безопасности эксплуатации и долговечности оборудования. В традиционных капсульных машинах основной причиной таких ударов является истирание и разрушение капсул из-за неточной центровки капсульной формы, в результате чего образуются обломки, заклинивающие механизмы. Что касается первопричины, то недостаточная точность индексирующего блока приводит к нарушению соосности капсульной формы.

Высококачественные промышленные машины для наполнения капсул бороться с этими проблемами можно с помощью надежных инженерных решений:

●Высокоточная разработка пресс-форм: Пресс-формы изготавливаются с использованием высокоточной механической обработки, обеспечивающей идеальную соосность верхней и нижней частей капсульной формы, что исключает брак капсул и образование засоряющих обломков.

●Полировка поверхности: Важные поверхности, включая заправочные стержни и отверстия капсульных форм, подвергаются электрополировке до зеркального блеска с целью улучшения текучести порошка и предотвращения его скопления. В результате обеспечивается бесперебойная работа компонента.

●Специальное покрытие: Для сложных порошковых составов в качестве опции предлагаются специальные покрытия, например, из тефлона, которые обеспечивают сверхгладкий, антипригарный барьер, практически исключающий проблемы с адгезией.

Ключевым фактором, обеспечивающим непрерывное производство капсул, является простота ежедневного технического обслуживания, что напрямую поддерживает стабильную производительность. Это достигается, прежде всего, за счет модульной архитектуры.

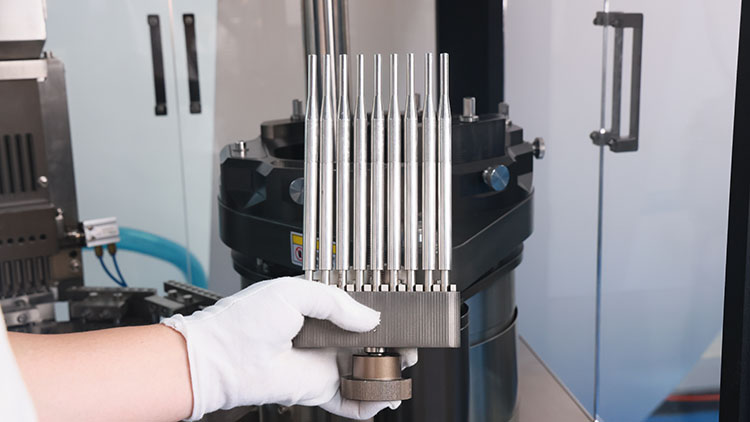

легко разбираемые стержни для порошкового наполнения

●Компоненты модульной конструкции: Такие детали, как модули заправочных стержней, спроектированы для быстрой разборки без специальных инструментов, что позволяет быстро проводить очистку при смене партий капсул и значительно минимизировать время простоя.

● Самосмазывающиеся подшипники: Для дальнейшего упрощения обслуживания автоматические машины для изготовления капсул оснащены компонентами, удобными для технического обслуживания. Например, использование самосмазывающихся полимерных подшипников в револьверной головке исключает необходимость ручной смазки.

●Интеллектуальная система смазки: Эта система использует автоматизированную систему смазки с замкнутым контуром, которая подает точное количество смазки к важным движущимся частям, таким как кулачки, через запланированные интервалы. Такая автоматизация исключает риски человеческой ошибки — как недостаточной смазки, вызывающей износ кулачков, так и чрезмерного количества масла, приводящего к загрязнению. В результате плановое техническое обслуживание становится предсказуемым, обеспечивая непрерывное и гигиеничное производство капсул.

Обычные автоматические машины для наполнения капсул, особенно те, у которых открытые внешние кулачки, страдают от структурной нестабильности и заметного шума. Неизбежные небольшие смещения во время работы на высоких скоростях приводят к нестабильному контакту с толкателями, генерируя ударный шум, который снижает удовлетворенность персонала и препятствует соблюдению нормативных требований.

В лучших капсульных станках эта проблема шума решается за счет использования цельнолитых внутренних кулачков, точно обработанных на станках с ЧПУ. Такая бесшовная конструкция обеспечивает стабильное движение компонентов трансмиссии, снижая уровень рабочего шума до менее 65 дБ, что делает рабочую среду более безопасной и соответствующей требованиям.

Указанные выше преимущества оборудования следует учитывать при выборе аппарата для наполнения капсул с лекарственными препаратами или пищевыми добавками из Китая. Что касается конкретных моделей, мы предлагаем 5 автоматических аппаратов для наполнения капсул, которые сочетают в себе все вышеперечисленные преимущества.

Эти 5 автоматических машин для изготовления капсул способны наполнять капсулы порошком, гранулами и пеллетами, а также обрабатывать капсулы размером от 000 до 5, автоматически и непрерывно выполняя производственные процессы: дозирование капсул, разделение капсул, наполнение капсул сырьем, отбраковка некачественных капсул, запирание капсул и выгрузка готовых капсул.

Как и аналогичные модели, такие как капсулоукладочная машина NJP 1200 и njp-3800, NJP-400C отличается точной дозировкой, стабильной работой и отсутствием пыли в рабочей среде, что соответствует требованиям cGMP. Максимальная производительность достигает 24 000 капсул в час.

Капсулозаполнительная машина NJP 400 разработана для плавной инкапсуляции, особенно сложных порошков. Ее инновационная пневматическая система подачи порошка обеспечивает превосходную точность наполнения даже для вязких, плохо сыпучих веществ. Кроме того, ее поворотная головка оснащена силиконовыми резиновыми уплотнениями, которые предотвращают попадание порошка внутрь, исключая загрязнение и механическое засорение.

Разработанная для простоты эксплуатации и обслуживания, установка njp400 оснащена самосмазывающимися подшипниками из ПТФЭ на двух горизонтальных валах поворотной головки, что исключает необходимость ручной смазки. Кроме того, держатели заправочных стержней имеют выдвижную конструкцию, позволяющую быстро менять различные модули стержней. Это оборудование идеально подходит для мелко- и среднемасштабного производства фармацевтических препаратов, традиционных лекарств и пищевых добавок.

Автоматический наполнитель капсул NJP-1500D Достигает максимальной производительности 90 000 штук в час, что подходит для массового производства фармацевтических и нутрицевтических капсул. Является одной из самых популярных коммерческих машин для наполнения капсул в Китае.

Эта модель разработана для обеспечения высокой производительности, надежности и соответствия стандартам cGMP. Ее техническое обслуживание упрощается благодаря интеллектуальной системе смазки от US Bijur, которая автоматически смазывает механизмы трансмиссии, обеспечивая плавную работу. Кроме того, интегрированный, бесшовно изготовленный кулачковый механизм с ЧПУ минимизирует шум во время высокоскоростных процессов герметизации, а формы с быстросъемной конструкцией со скользящим пазом позволяют полностью заменить заправочный стержень менее чем за 15 минут. Более того, стабильность работы и долговечность гарантируются за счет интеграции всемирно известных электрических компонентов, включая систему ПЛК Siemens и человеко-машинный интерфейс, реле и контакторы Schneider, частотный преобразователь Omron и вакуумный насос Becker.

Благодаря максимальной производительности в 156 000 капсул в час, машина NJP-2600D обладает более высокой эффективностью инкапсуляции по сравнению с машиной для наполнения капсул NJP-1500D.

Эта машина для наполнения капсул разработана для высокой точности и эффективности. Ее механизм наполнения использует трехмерную регулировку для обеспечения равномерного распределения усилия на дозирующем диске, что позволяет точно регулировать дозировку. Кроме того, интегрированная система рекуперации порошка обеспечивает 100% повторное использование порошка, повышая экономическую выгоду. Для решения проблем с плохо текучими порошками, такие важные компоненты, как заправочные стержни и отверстия в капсульной форме, подвергаются электронной полировке и обрабатываются тефлоновым покрытием, предотвращающим прилипание порошка к поверхностям. Более того, формы изготавливаются с идеальной концентричностью и нулевым отклонением, что гарантирует отсутствие царапин и повреждений капсул во время вращения револьверной головки. Все эти конструктивные особенности обеспечивают непрерывную и стабильную работу оборудования.

Данная модель обладает максимальной производительностью 468 000 капсул в час, что делает ее более мощным оборудованием для производства капсул в крупномасштабном фармацевтическом производстве лекарственных препаратов или капсул для пищевых добавок.

Исходя из приведенного выше описания, капсулоукладочная машина NJP-3800 разделяет схожую с ее предшественниками философию научного проектирования. Она придерживается структурированной и модульной концепции, обеспечивая простоту эксплуатации и чрезвычайно низкий уровень отказов при крупномасштабном производстве капсул.

Более того, этот автоматический аппарат для наполнения капсул оснащен пневматической системой очистки пресс-форм с использованием сжатого воздуха. Эта функция активно поддерживает чистоту как верхней, так и нижней пресс-форм, что крайне важно для повышения качества готовых капсул и долгосрочной стабильности оборудования за счет решения проблем, связанных с загрязнением.

Упомянутые выше 4 модели машин полностью автоматизированы, но как быть с производством капсул в небольших масштабах, которое все же требует некоторой автоматизации операций? Здесь мы рассмотрим полуавтоматическую модель изготовления капсул.

Полуавтоматическая машина для производства желатиновых капсул CGNT-209, в отличие от других полуавтоматических машин, требует ручной работы по разделению капсул, утрамбовке порошка и запечатыванию капсул, но с учетом ручного труда, она способна производить до 40 000 капсул в час на максимальной скорости.

В отличие от традиционного полуавтоматического оборудования, эта машина для капсулирования представляет собой усовершенствованную конструкцию, повышающую эффективность и точность работы. Ключевым нововведением является двухрядное устройство подачи капсул, которое удваивает производительность по сравнению с однорядными наполнителями. Эффективность обеспечивается интегрированной электромеханической и пневматической системой управления, регулирующей три основные станции — подачу капсул, наполнение и фиксацию. Эта интеграция обеспечивает плавную координацию между каждым этапом, увеличивая скорость наполнения. Кроме того, точность дозирования контролируется путем регулирования скорости подачи порошка и скорости перемещения пресс-формы, обеспечивая погрешность веса наполнения в пределах 3%.

Оборудование для наполнения капсул серии njp обладает множеством преимуществ, которые не рассматриваются в данной статье. В будущей практике капсулирования вы можете обратиться к опытным специалистам. профессионалы по машинам для наполнения капсул для предоставления инструкций пользователям и технической поддержки.

Топ-5 автоматических машин для наполнения капсул из Китая, таких как серия NJP, отличаются сочетанием точного наполнения, стабильной длительной работы и непрерывного соответствия нормативным требованиям. Наблюдается тенденция к увеличению количества машин для наполнения капсул в Китае, которые оснащаются системами контроля доступа, многоуровневым управлением паролями, журналом аудита и электронной подписью, что обеспечивает надежную работу и соответствие строгим международным требованиям фармацевтического производства. Если вам нужно выбрать машины для наполнения капсул, обратите внимание на китайских поставщиков.