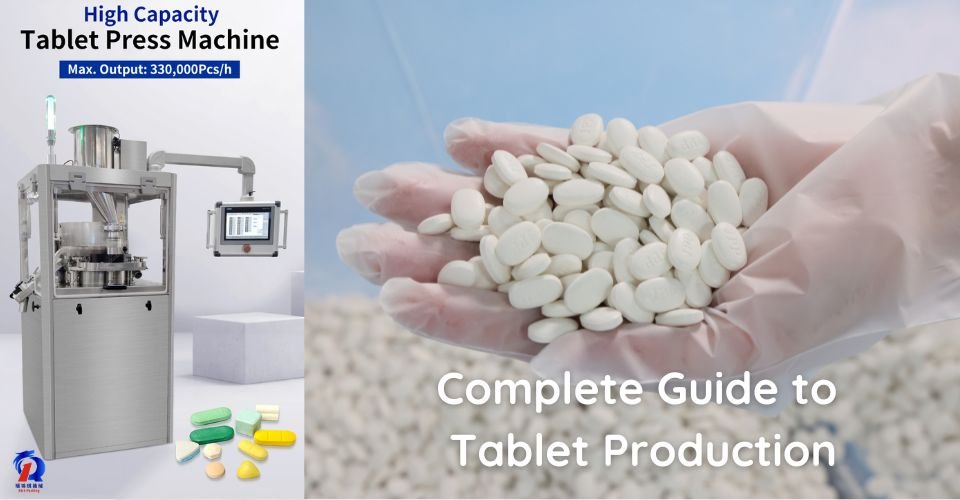

Вы когда-нибудь задумывались о процессе производство таблеток или прессование таблеток ? Это — это кропотливый процесс, имеющий решающее значение для создания фармацевтических препаратов и других таблеток. В т его статью, мы будем описать процесс прессования таблеток шаг за шагом, от подготовки сырья до окончательной проверки качества, предлагая важнейшие знания для производителей, стремящихся к совершенству.

Каждый отличный продукт начинается с высококачественных ингредиентов, и производство таблеток Не является исключением. Правильная подготовка гарантирует готовность материалов к следующему этапу, открывая путь к стабильным и высококачественным результатам. Ниже приведены некоторые ключевые моменты, которые следует учитывать при подготовке ингредиентов.

• Инспекция сырья : Прежде всего, сырье должно быть тщательно проверено на соответствие требуемым стандартам. Каждый ингредиент должен быть проверен на чистоту, содержание влаги и размер частиц. Любые несоответствия на этом этапе могут привести к получению таблеток низкого качества.

• Смешивание и смешивание : После проверки материалы необходимо смешать до однородности. Равномерное смешивание гарантирует, что каждая таблетка содержит правильные пропорции активных и вспомогательных веществ. Это особенно важно для фармацевтической продукции, где точность дозировки не подлежит обсуждению.

• Гранулирование (при необходимости) : В некоторых случаях порошки могут нуждаться в грануляции для улучшения их сыпучести. Грануляция преобразует мелкие порошки в более крупные, сыпучие гранулы, которые легче прессовать в таблетки. Существуют специальные машины, например, сухие и мокрые грануляторы.

2. Выбор подходящего таблеточного пресса

2. Выбор подходящего таблеточного пресса

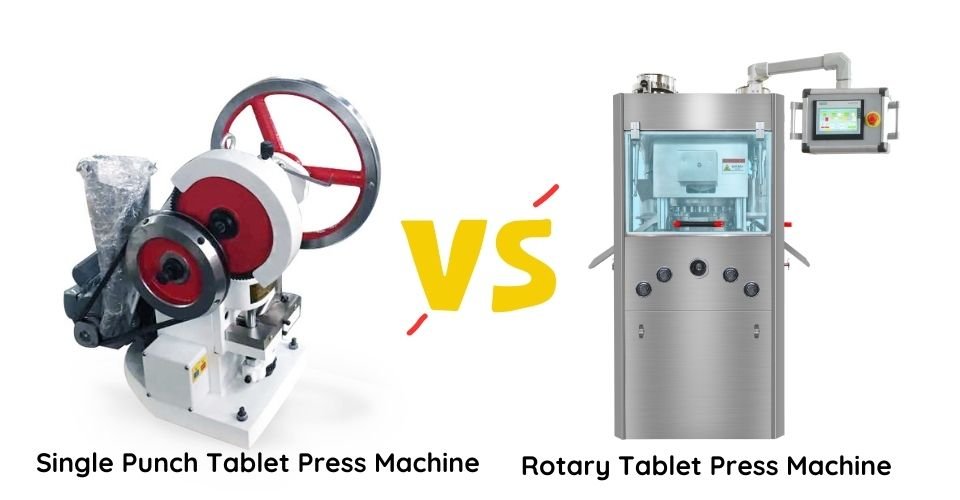

При выборе таблеточного пресса важно понимать: Ваши потребности в производстве с точки зрения производственной мощности, гибкости или других особых требований. В зависимости от скорости производства, ниже приведены два основных типы таблеточных прессов часто встречается на рынке.

• Однопуансонный таблеточный пресс: Лучше всего подходит для мелкосерийного или экспериментального производства, поскольку отличается меньшими затратами и более простой эксплуатацией. Этот тип таблеточный пресс также поставляются с полуавтоматическими или полностью автоматическими опциями в зависимости от клиентов ' требования.

• Автоматический роторный таблеточный пресс : Идеально для от среднего до крупномасштабное производство с высокой скоростью, автоматизированной точностью и стабильным качеством. Обычно этот тип машина для прессования таблеток имеется возможность прессовать таблетки разных размеров и форм путем простой смены форм.

Для лучшего понимания этих двух типов машин мы создали таблицу ниже, в которой объясняются их плюсы и минусы.

|

Тип машины |

Однопуансонный таблеточный пресс |

Автоматический роторный таблеточный пресс |

|

Операция |

Ручной или полуавтоматический режим. Прессуется одна таблетка за раз. |

Полностью автоматизирован, непрерывно прессует таблетки вращательным движением. |

|

Плюсы |

• Низкие первоначальные затраты. • Простота эксплуатации и обслуживания. • Гибкий для мелкосерийное производство. • Идеально подходит для исследований и разработок. |

• Высокоскоростное производство, способное выпускать тысячи таблеток в минуту. • Превосходная последовательность и точность. • Полностью автоматизировано, что сокращает ручной труд. • Подходит для крупносерийного производства. |

|

Минусы |

• Низкая скорость производства (одна таблетка за раз). • Ограниченная масштабируемость для крупносерийного производства. • Менее последовательный • Требует больше ручного труда и внимания. |

• Более высокая первоначальная стоимость. • Требуются квалифицированные операторы для устранения неисправностей. • Более высокая сложность, требующая обслуживания большего количества деталей. |

При выборе таблеточного пресса для вашего прессование таблеток Помимо производственной мощности, есть еще несколько характеристик, которые вам следует учитывать:

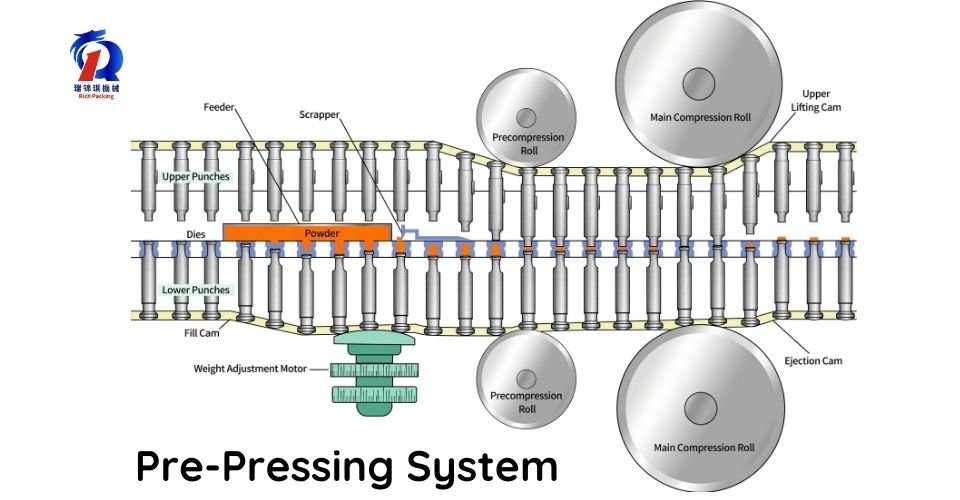

• Сила сжатия: Регулируемое усилие необходимо для контроля твёрдости таблеток. Для более твёрдых материалов и более крупных таблеток требуется большее усилие. Для более крупного производства рекомендуется выбирать машины с функцией предварительного прессования, поскольку она играет ключевую роль в обеспечении качества при сохранении высокой скорости производства.

• Легкий Регулируемые настройки: Ищите машины, которые позволяют легко регулировать параметры штампа по весу, толщине и объему заполнения. машина для прессования таблеток более целесообразно использовать интерфейс ПЛК ведущих марок.

• Универсальность и гибкость: Поскольку таблеточные прессы, особенно высокоскоростные роторные, требуют значительных финансовых вложений, лучше выбирать более универсальные и гибкие модели. Например, высокоскоростной таблеточный пресс, позволяющий производить различные виды продукции путём простой смены пресс-форм.

• Удобный дизайн: Техническое обслуживание машины также очень важно, поэтому удобная для пользователя конструкция, например модульная, позволяющая оператору разбирать или чистить детали, окажет большую помощь.

Подготовив ингредиенты и установив необходимое оборудование, можно приступать к самому процессу прессования. Этот этап включает в себя несколько тщательно выполняемых этапов:

• Загрузка пороха : Подготовленный порошок или гранулы загружаются в бункер таблеточный пресс . Для производства большего количества таблеток можно добавить вакуумный питатель для обеспечения непрерывной и стабильной подачи в прессующий механизм.

• Настройка параметров сжатия : Перед началом работы установите усилие прессования и параметры пресс-формы в соответствии с желаемым размером, формой и твёрдостью таблетки. Точные настройки имеют решающее значение для достижения стабильных результатов.

• Выполнение тестовых партий : Всегда проводите тестовые партии, чтобы убедиться, что таблетки соответствуют требуемым спецификациям. Тестовые запуски позволяют вносить коррективы, не тратя время и материалы.

• Полномасштабное производство : После оптимизации настроек машина может работать на полную мощность.

Этот процесс превращает рассыпчатые порошки в однородные, компактные таблетки, готовые к упаковке и распространению. Если вы хотите узнать больше о процессе производства, посмотрите это видео.

Даже при лучшей подготовке и оборудовании во время работы могут возникнуть проблемы. процесс прессования таблеток . Ниже приведены несколько распространённых проблем и способы их решения:

• Неравномерное сжатие : Если некоторые таблетки мягче или твёрже других, порошок может неравномерно поступать в полость пресс-формы. Чтобы решить эту проблему, убедитесь, что материалы правильно гранулированы, и при необходимости используйте усилители текучести.

• Трещины или поломки планшета : Таблетки могут треснуть во время прессования, если приложить слишком большое усилие или если в порошке останется воздух. Предварительное прессование, при котором перед основным прессованием прикладывается небольшое усилие, может предотвратить эту проблему.

• Приклеивание или укупорка Прилипание порошков к машине или расслоение таблеток часто вызваны избыточной влажностью или недостаточной смазкой. Корректировка рецептуры или использование смазочных материалов могут решить эти проблемы.

Понимание и решение этих проблем на ранних этапах обеспечивает более плавный производственный процесс и сокращает отходы материалов.

Перед упаковкой и распространением таблеток они должны пройти строгий контроль качества, чтобы убедиться в их соответствии всем спецификациям.

• Проверка твердости, толщины и веса : Эти испытания проверяют единообразие размеров каждой таблетки и её соответствие требуемым физическим свойствам. Автоматизированные системы позволяют проводить эти проверки в режиме реального времени в процессе производства.

• Обеспечение однородности партии : Каждую партию необходимо проверять на однородность. Любые отклонения могут указывать на проблемы на этапах смешивания, грануляции или прессования.

• Использование пылеуловителя : После прессования на поверхности таблеток часто остаётся излишек порошка. Обеспыливающая машина удаляет этот порошок, оставляя таблетки чистыми и готовыми к упаковке.

Этот заключительный этап гарантирует, что на рынок попадут только высококачественные планшеты, защищая как потребителей, так и репутацию вашего бренда.

Этот заключительный этап гарантирует, что на рынок попадут только высококачественные планшеты, защищая как потребителей, так и репутацию вашего бренда.

Прессование таблеток Это сложный, но результативный процесс, требующий точности, подходящего оборудования и внимания к деталям. Каждый этап, от подготовки сырья до проведения финального контроля качества, играет важнейшую роль в производстве безопасных, эффективных и стабильных таблеток.

Тем, кто стремится повысить эффективность своего производства, крайне важно инвестировать в высококачественные таблеточные прессы. Следуя инструкциям, представленным в этом руководстве, вы сможете оптимизировать свой производственный процесс и производить таблетки, соответствующие самым высоким отраслевым стандартам.